Selective Laser Sintering (SLS)

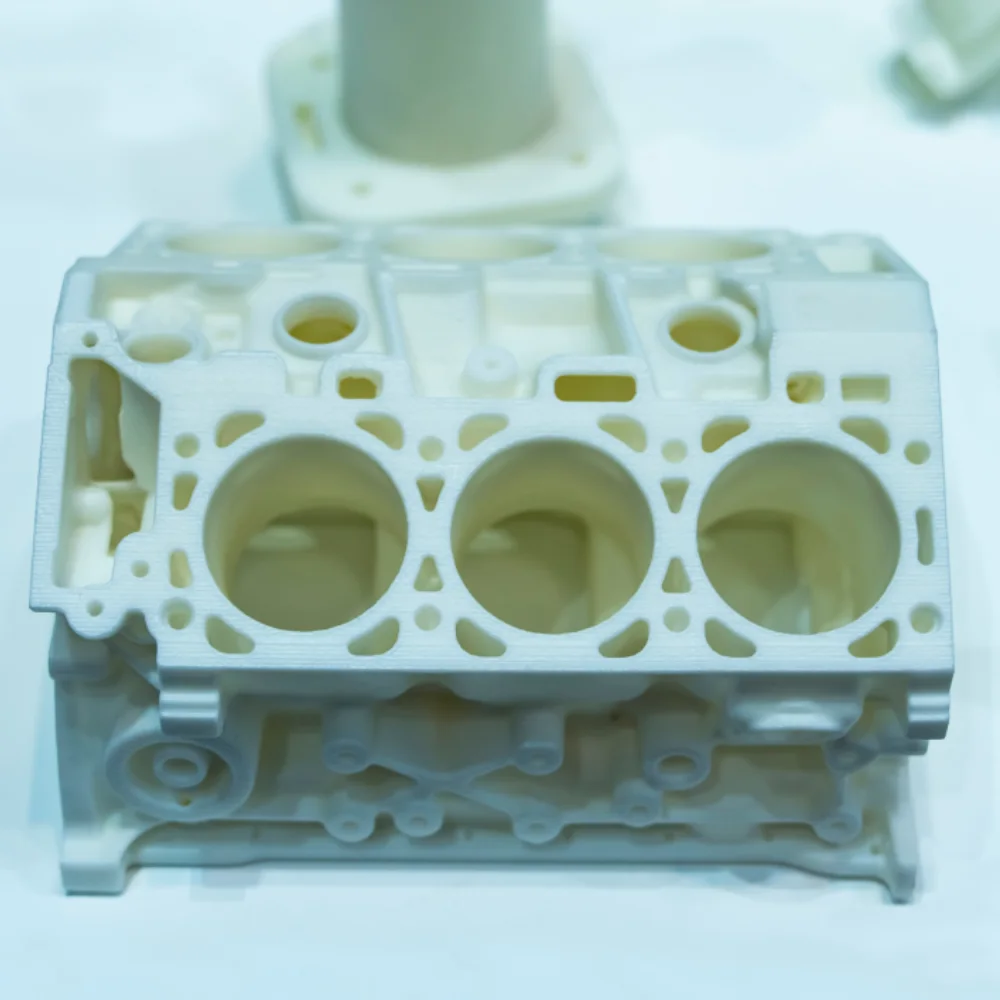

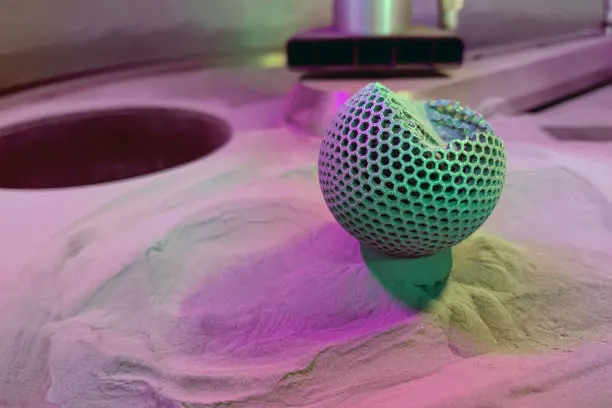

Selective Laser Sintering (SLS) uses a high-power laser to fuse small particles of nylon-based polymer powder. Its greatest advantage is that it requires no support structures, as the surrounding unsintered powder supports the part during printing. This allows for incredible design freedom and the creation of complex, interlocking geometries. SLS parts are strong, durable, and have good mechanical properties, making them ideal for functional prototypes and end-use parts.

How does SLS 3D Printing work?

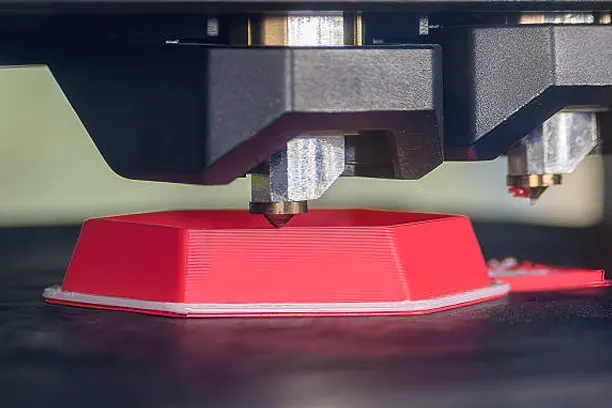

Selective Laser Sintering (SLS) is a powder bed fusion process. It begins with a build chamber heated to just below the melting point of its polymer powder, typically nylon. A recoating blade or roller spreads a very thin layer of this powder across the build platform.

A high-power CO₂ laser then scans the cross-section of the part, selectively sintering the powder particles by heating them to just beyond their melting point. This fuses the particles together to form a solid layer. The surrounding unsintered powder remains in place, naturally supporting the part and any overhangs, eliminating the need for dedicated support structures.

Upon completing a layer, the build platform lowers by one layer thickness, and the recoater applies a new layer of powder. The process repeats until the entire part is complete. After printing, the entire "cake" of powder must cool gradually to prevent warping. The parts are then excavated from the powder bed and undergo post-processing, such as bead blasting, to remove any excess, unsintered powder, resulting in strong, functional components.

Our SLS 3D Printing Machines

|

Process |

Brand |

Model |

Numbers |

Printing Size(mm) |

PRINTING ACCURACY(MM) |

|---|---|---|---|---|---|

|

SLS |

RedWax |

280 |

25 |

192*128*280 |

0.1-0.2 |

|

SLS |

RedWax |

300 |

25 |

224*198*300 |

0.1-0.2 |

Available Finishes

SLS do not have supports needed.

1. Polishing

2. Braces

3. Copper nut