Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a metal additive manufacturing process that uses a high-power laser to fully melt and fuse metallic powder particles together, layer by layer. It creates near-net-shape parts with exceptional density, often over 99.5%, resulting in excellent mechanical properties that are comparable to wrought materials. SLM achieves high complexity and fine detail, but requires specialized support structures to mitigate thermal stress and warping.It is renowned for producing robust, functional metal components for aerospace, medical, and high-performance industries.

How does SLM 3D Printing work?

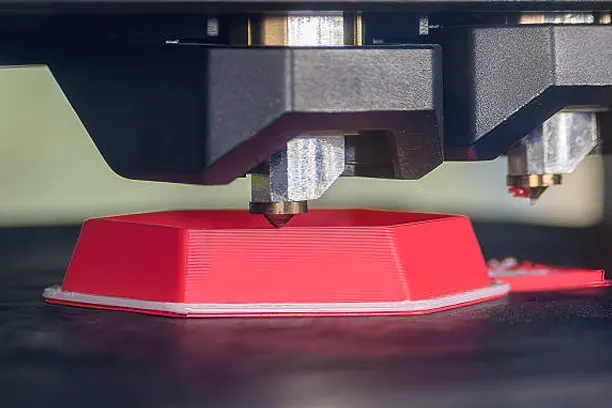

Selective Laser Melting (SLM) is an additive manufacturing process that creates fully dense metal parts. It occurs inside a sealed chamber filled with an inert gas, like argon, to prevent oxidation. A recoater blade first spreads a thin layer of fine metal powder over a build platform.

A high-power fiber laser then scans the cross-section of the part, selectively melting and completely fusing the metal powder particles together according to the digital model's design. The entire powder bed remains solidly in place, but only the areas struck by the laser are melted into a solid layer. This layer then cools and solidifies rapidly.

After a layer is complete, the build platform descends, a new layer of powder is applied, and the process repeats, with each new layer bonding to the one below it. The unsintered powder surrounding the part acts as a support, though dedicated supports are often still needed to anchor the part and manage heat dissipation. Once the build is finished, the entire powder cake must cool before the solid part can be excavated. The final component then undergoes necessary post-processing, including heat treatment to relieve internal stresses and support removal.

Our SLM 3D Printing Machines

|

Process |

Brand |

Model |

Numbers |

Printing Size(mm) |

PRINTING ACCURACY(MM) |

|---|---|---|---|---|---|

|

SLM |

BLT |

350 |

15 |

280*280*350 |

0.2-0.4 |

|

SLM |

BLT |

380 |

15 |

280*280*380 |

0.2-0.4 |

Available Finishes

SLM parts are built with support material that is removed during post-processing. The part surfaces are left with fine layer lines.

1. Tapping and tapping teeth

2. Heat treatment

3. Electrophoresis

4. Polishing

5. Grinding

6. Electroplating