Digital Light Processing (DLP)

Digital Light Processing (DLP) 3D printing cures liquid photopolymer resin using a digital light projector screen. This method exposes entire layers simultaneously, making it significantly faster than laser-based SLA for full-build platforms. It achieves high accuracy and a smooth surface finish, similar to SLA. However, the pixel-based curing can sometimes create a subtle voxel pattern on surfaces. Like SLA, DLP parts require support structures and extensive post-processing, including washing and UV curing, to achieve final strength and stability.

How does DLP 3D Printing work?

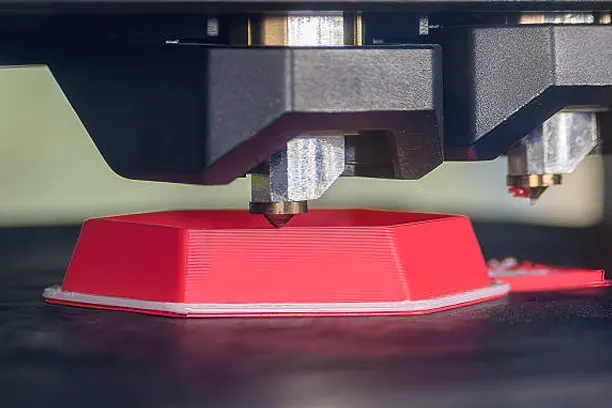

Digital Light Processing (DLP) 3D printing is a vat polymerization technology similar to SLA. The key difference is its light source. Instead of a laser, DLP uses a digital light projector screen to flash a single, complete image of each layer all at once. This projector is typically a high-resolution LCD or a dedicated DLP chip.

This process begins with a vat of liquid photopolymer resin. The build platform starts just one layer-height below the resin's surface. For each layer, the projector displays a UV light image, curing and solidifying the entire cross-section of the object simultaneously. The platform then lifts, allowing uncured resin to flow underneath. It descends again, and the process repeats for the next layer.

This layer-by-layer exposure builds the object from the bottom up. After printing, the part requires removal from the platform, washing in a solvent like isopropyl alcohol to remove excess resin, and a final post-cure under UV light to achieve maximum mechanical strength and stability.

Our DLP 3D Printing Machines

|

Process |

Brand |

Model |

Numbers |

Printing Size(mm) |

PRINTING ACCURACY(MM) |

|---|---|---|---|---|---|

|

DLP |

RedWax |

280 |

25 |

192*128*280 |

0.1-0.2 |

|

DLP |

RedWax |

300 |

25 |

224*198*300 |

0.1-0.2 |

Available Finishes

DLP parts are built with support material that is removed during post-processing. The part surfaces are left with fine layer lines.

1. Spray painting

2. Electroplating

3. Braces

4. Copper nut