Multi Jet Fusion (MJF)

HP's Multi Jet Fusion (MJF) uses an inkjet array to deposit fusing and detailing agents onto a bed of nylon powder, which is then fused by infrared energy. It excels at producing strong, functional, and isotropic parts with high dimensional accuracy. Unlike SLS, it requires no supports, enabling efficient packing of parts. MJF is renowned for its high speed and scalability for end-use production, offering excellent surface quality and fine feature resolution. However, it is primarily limited to nylon-based materials and parts have a porous, matte finish straight from the printer.

How does MJF 3D Printing work?

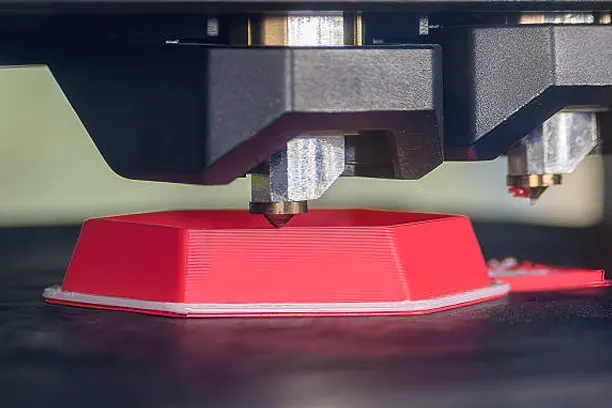

HP's Multi Jet Fusion (MJF) is a powder bed fusion process that builds parts layer by layer. It begins with a thin layer of polymer powder, typically nylon, being spread across a build platform. An inkjet array then precisely jets two agents onto the powder: a fusing agent where the part is to be formed, and a detailing agent around its edges to ensure precision.

Immediately after, an infrared energy lamp passes over the entire bed. This radiation heats and fuses the powder particles that have been coated with the fusing agent, solidifying the cross-section. The surrounding powder, untreated or cooled by the detailing agent, remains loose and acts as a natural support, allowing for complex geometries without dedicated structures.

Once a layer is complete, the platform lowers, a new powder layer is applied, and the process repeats. After printing, the entire "cake" of powder and parts must cool before being excavated. The parts are then bead-blasted to remove excess powder, resulting in strong, functional components ready for use or further post-processing.

Our MJF 3D Printing Machines

|

Process |

Brand |

Model |

Numbers |

Printing Size(mm) |

PRINTING ACCURACY(MM) |

|---|---|---|---|---|---|

|

MJF |

HP |

5200PRO |

15 |

380*280*380 |

0.2-0.4 |

|

MJF |

HP |

5620PRO |

15 |

380*280*380 |

0.2-0.4 |

MJF Printing Materials

Black Nylon

White Nylon

Grey Nylon

Available Finishes

MJF do not have supports needed.

1. Polishing

2. Braces

3. Copper nut