Stereolithography (SLA)

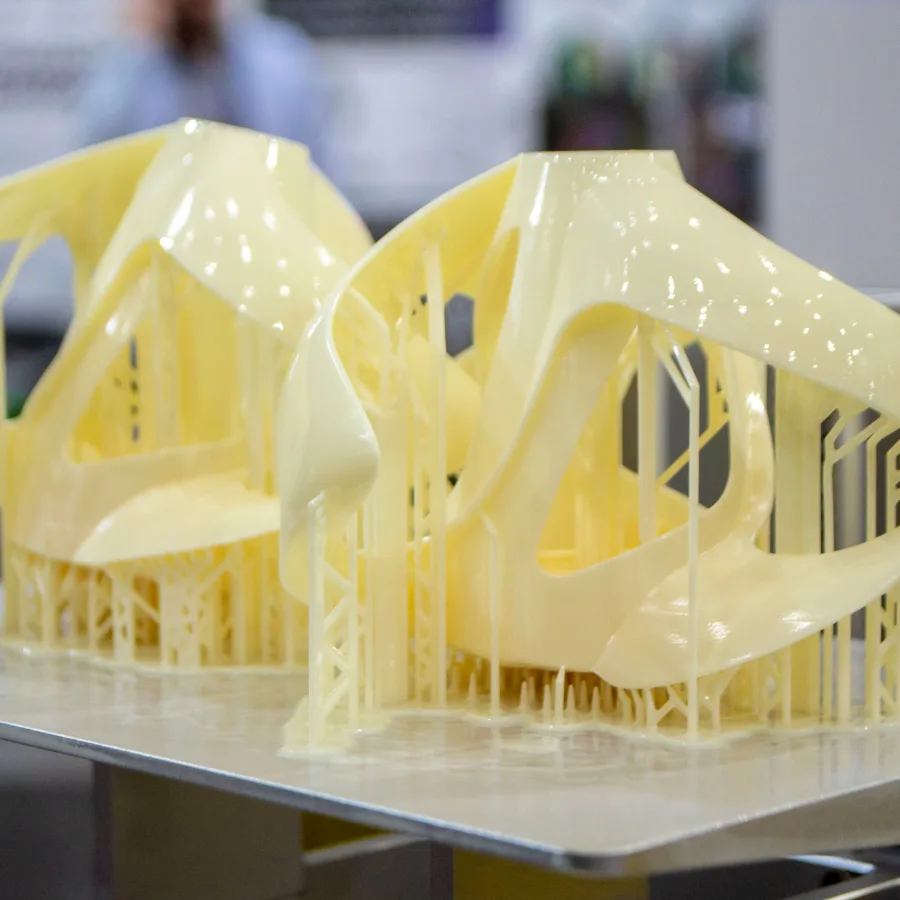

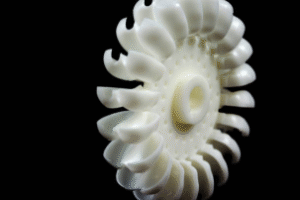

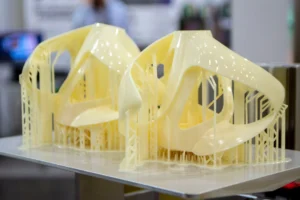

Stereolithography (SLA) uses a laser to cure liquid resin into hardened plastic, producing parts with exceptional surface finish, high resolution, and fine details. It offers excellent accuracy for complex geometries, making it ideal for prototypes, molds, and models requiring smooth surfaces. However, SLA parts are often brittle and susceptible to UV degradation. Support structures are necessary and must be removed post-processing. The process involves post-curing under UV light to achieve full strength and stability.

How does SLA 3D Printing work?

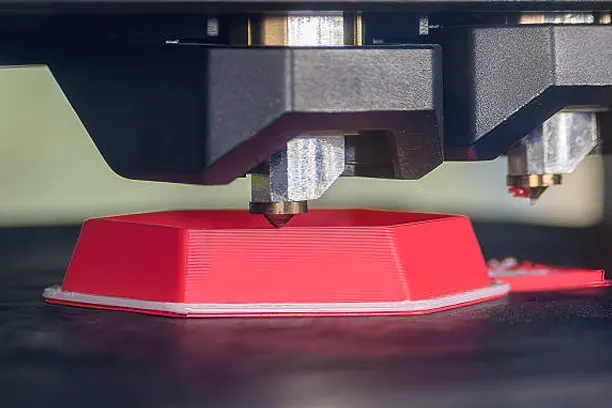

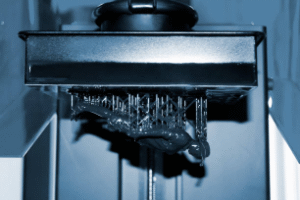

Stereolithography (SLA) is a vat photopolymerization process. It begins with a build tank filled with liquid UV-curable resin. A UV laser beam is precisely focused onto the resin surface, tracing a cross-section of the 3D model. Where the laser hits, the resin instantly hardens (cures) into solid plastic.

After one layer is complete, the build platform lowers, submerged in the tank. A recoating blade then sweeps across the surface, ensuring a fresh, thin layer of resin covers the previous part. The laser proceeds to cure the next layer, bonding it to the one below. This cycle repeats, building the object upside-down, layer by layer, from the bottom up.

Once printing is finished, the object is carefully removed. It requires post-processing: washing in a solvent to remove excess sticky resin and subsequent curing in a UV oven. This final curing step fully solidifies the resin, achieving the part’s optimal strength and stability.

Our SLA 3D Printing Machines

|

Process |

Brand |

Model |

Numbers |

Printing Size(mm) |

PRINTING ACCURACY(MM) |

|---|---|---|---|---|---|

|

SLA |

UnionTech |

450 |

200 |

450*450*350 |

0.15-0.3 |

|

SLA |

UnionTech |

600 |

200 |

600*600*400 |

0.15-0.3 |

|

SLA |

UnionTech |

800 |

200 |

800*800*500 |

0.15-0.3 |

|

SLA |

UnionTech |

1400 |

200 |

1400*700*500 |

0.15-0.3 |

|

SLA |

UnionTech |

1800 |

200 |

1800*900*700 |

0.15-0.3 |

SLA Printing Materials

White Resin

Yellow Resin

Black Resin

Transparent Resin

Grey 90℃ Resin

White 140℃ Resin

Available Finishes

SLA parts are built with support material that is removed during post-processing. The part surfaces are left with fine layer lines.

1. Spray painting

2. Electroplating

3. Screen printing

4. Braces

5. Copper nut