High-Volume & Large-Format 3D Printing Solutions

Unlock the power of 3D Printing in mass quantities for your business and elevate your production with our state-of-the-art 3D Print Farm and Large-Scale capabilities.

- Lead times as fast as 1-day

- Quantity pricing available

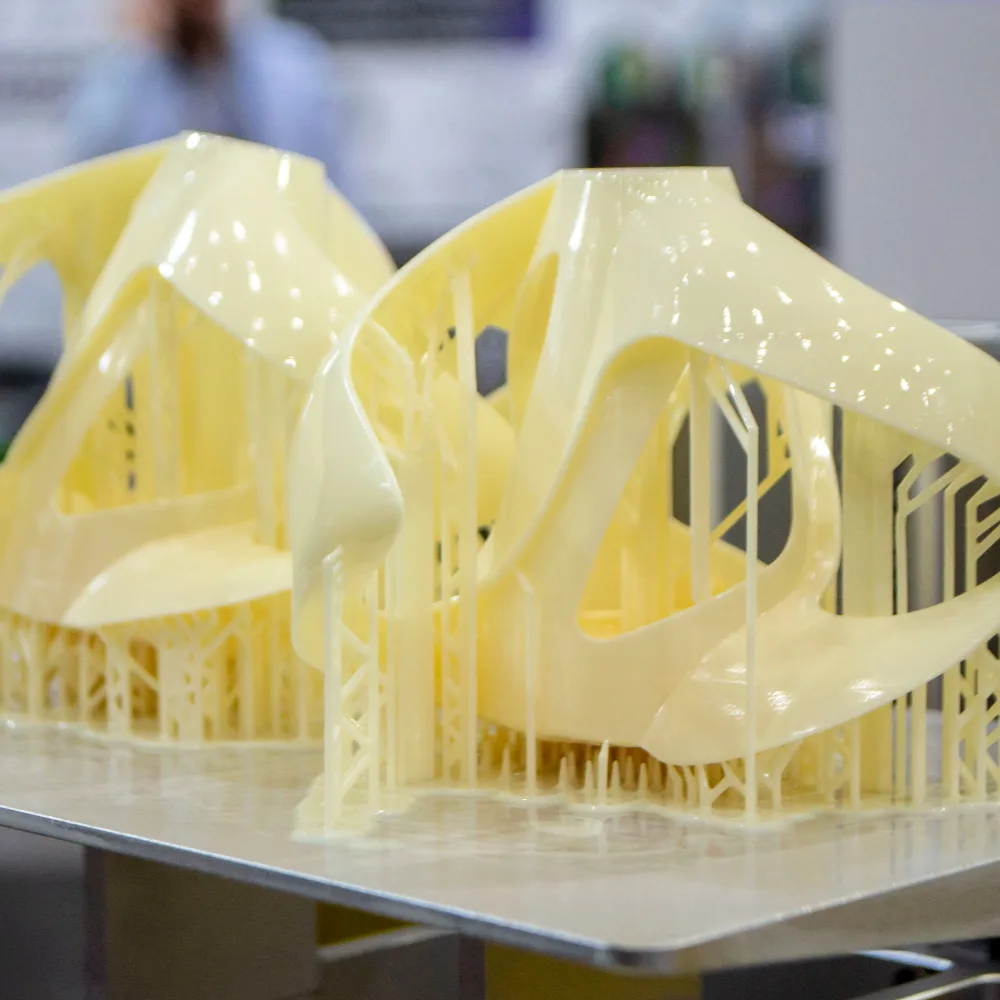

Our 3D Printing Technology

Comparison of Various 3D Printing Methods

|

FDM |

SLA |

DLP |

MJF |

SLS |

SLM |

|

|---|---|---|---|---|---|---|

|

Principle |

Extrudes melted |

UV laser cures liquid resin |

UV projector cures entire layer at once |

Inkjet agents fuse nylon powder |

Laser sinters polymer powder |

High-power laser fully melts metal powder |

|

Materials |

PLA, ABS, ASA, PETG,

TPU, PC, Nylon, HIPS, POM, PP, PVA |

Photopolymers |

Red wax, Brown wax, Soft silicone |

Nylon (PA12), TPU |

Nylon (PA11/PA12), TPU |

Aluminum, Titanium, Stainless Steel |

|

Material Colors |

Black, White, Red, |

Black, White, Yellow, Gray, Transparent |

Red, Brown, Black, White, Transparent |

Grey, Black, White |

White |

Silver, Metal |

|

Machine Quantity(sets) |

1040 |

700 |

50 |

40 |

20 |

25 |

|

Max Print Size(mm) |

1200 * 1200 * 1000 |

1700 * 800 * 550 |

320 * 200 * 190 |

380 * 284 * 380 |

600 * 360 * 360 |

420 * 380 * 280 |

|

Printing Accuracy(mm) |

0.1-0.5 |

0.05-0.3 |

0.05-0.3 |

0.05-0.2 |

0.2-0.4 |

0.2-0.4 |

|

Layer Quality |

★★★ |

★★★★☆ |

★★★★★ |

★★★☆ |

★★★ |

★★★★ |

|

Material Strength |

★★★ |

★★ |

★★ |

★★★☆ |

★★★★ |

★★★★★ |

|

Post-Processing |

• Grinding |

• Spray painting |

• Spray painting |

• Grinding |

• Grinding |

• Tapping |

|

Pros |

• Lowest material cost |

• High accuracy |

• Faster than SLA |

• Fast production speed |

• No supports needed |

• Fully dense metal parts |

|

Cons |

• Visible layer lines |

• Brittle parts |

• Pixelated edges |

• Rough surface texture |

• Limited material options |

• Extremely high cost |

|

Best For |

Prototypes, Education, Low-cost parts |

Jewelry, Dental, Miniatures |

Detailed prototypes, Dental aligners |

Batch production, Functional assemblies |

Functional prototypes, End-use parts |

Aerospace, Medical implants |

Finishing Services

FDM

1. Polishing

2. Braces

3. Copper nut

SLA

1. Spray painting

2. Electroplating

3. Screen printing

4. Braces

5. Copper nut

DLP

1. Spray painting

2. Electroplating

3. Braces

4. Copper nut

MJF

1. Polishing

2. Braces

3. Copper nut

SLS

1. Polishing

2. Braces

3. Copper nut

SLM

1. Tapping and tapping teeth

2. Heat treatment

3. Electrophoresis

4. Polishing

5. Grinding

6. Electroplating

3D Printing FAQ

We offer a full spectrum of 3D printing services, including rapid prototyping, functional testing, custom end-use parts production, and low-volume manufacturing. We also provide design consultation, file optimization, and post-processing finishing.

We work with a wide range of materials, including various plastics (PLA, ABS, PETG, Nylon, TPU), engineering-grade resins (Standard, Tough, Durable, High-Temp), and metals (Stainless Steel, Aluminum, Titanium). Browse our materials page for detailed properties.

Simply send us your 3D model file (e.g., .STL, .OBJ) , tell us your full quirements and quantities. We will calculate a price based on the volume, material, and finishing options you select.

We prefer .STL or .OBJ files for 3D printing. For quoting and design analysis, we can also accept native format files like .STEP, .IGES, or .SLDPRT.

Lead times vary based on technology, part size, and order volume. Standard lead times are 1-5 business days for printing, plus additional time for complex post-processing and shipping. We also offer rush services for urgent projects.

This depends on the material and technology. As a general rule, we recommend a minimum wall thickness of 1-2mm for plastics and 0.5-1mm for high-resolution resins. Thinner features may be possible but require careful design.

Accuracy depends on the technology. SLA and DLP resins can achieve details as fine as 25-100 microns. FDM printers typically range from 100-200 microns. Metal DMLS/SLM processes offer high accuracy around 30-50 microns.

Yes, for certain technologies. We offer full-colour sandstone printing for vibrant, multi-colour models. For plastics, we offer a wide palette of standard colours. Please inquire for specific colour matching (Pantone) requests.

We offer a variety of finishes including:

Standard: Support removal and light sanding.

Smooth: Sanding, priming, and painting.

Professional: Vapor smoothing (for ABS), high-gloss polishing, and expert hand-painting.

Functional: Machining, tapping, and other secondary operations.

Every order undergoes a quality control check. We inspect dimensions against your drawings (if provided), check for visual defects, and ensure the finish meets the ordered specifications. We can also provide inspection reports upon request.

Customer satisfaction is our priority. Please contact us immediately upon receipt. We will work with you to understand the issue and find a solution, which may include re-printing the part or providing a refund, according to our terms and conditions.

Parts are carefully packaged to prevent damage during transit. Fragile parts are wrapped in bubble wrap and placed in sturdy boxes with sufficient padding. We use recyclable packaging materials where possible.